The importance of fin choice is often overlooked by many when fine tuning an equipment set up. Considered as important as board and sail choice by many a pro, understanding how a fin works and which one works for you is a tricky matter. Dave Gollick, certainly understands a lot about the shaping and making of fins, here he joins Boards to get a bit scientific and give you an in depth explanation of exactly what happens under the water.

There are a lot of different shapes around at the moment and no doubt every fin maker will tell you their fin is the best.

Let’s look through the basics and break it down, so we can understand ourselves the theory of what a fin does.

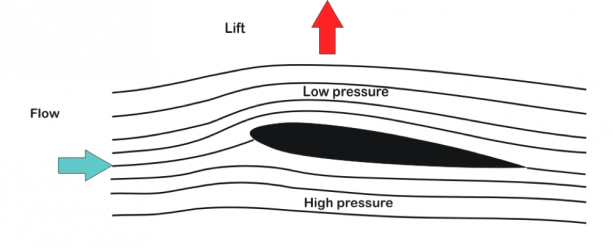

Firstly the foil (the curve of the fin, similar to the shape of an aeroplane wing) has to be good at keeping the water on its surface; if the flow of water over the foil (technically called the envelope of laminar flow) breaks then you get spin out. Bad, cheaply produced foils can cause this effect, therefore it is vital to consider how a fin is made and the accuracy of the construction.

Most fins these days are made in large facilities in China and many are still produced by hand shaping. These are not necessarily bad fins, but there can be a difference in these when compared to say a CNC (Computer Numerically Controlled) machined fin. CNC fins are more expensive but are a lot more accurate and therefore produce a better performance.

The other technology used involves a mould being produced, the fin is constructed with a layup of material, usually carbon and glass and then pressed under pressure. Another system is where prepreg (a term for “pre-impregnated” composite fibres where a material, such as epoxy is already present) material is used in the moulding process this contains resin and under heat this bonds the sheets of carbon and glass together. This process is then pressurised under extreme pressure to produce a very compact construction, this is used by Select Fins.

So, other than construction, what makes a good fin?

The accuracy of the foil and the material used is vital, so is the profile or outline shape. For example the majority of slalom fins use one of two templates.

The first is a trapezoid profile this is a modern looking shape, that has been adopted by many and has the ability to pass through the water efficiently. The second shape is classed as an elliptical plan form. This is thought of as an old shape by many, but in theory is one of the most efficient water passing shapes and it resembles a Spitfire wing. There are many other factors which affect the efficiency of the fin through the water such as the foil shape, the chord width and thickness of the foil.

The first is a trapezoid profile this is a modern looking shape, that has been adopted by many and has the ability to pass through the water efficiently.

The second shape is classed as an elliptical plan form. This is thought of as an old shape by many, but in theory is one of the most efficient water passing shapes and it resembles a Spitfire wing.

There are many other factors which affect the efficiency of the fin through the water such as the foil shape, the chord width and thickness of the foil.

The Fin

Definitions

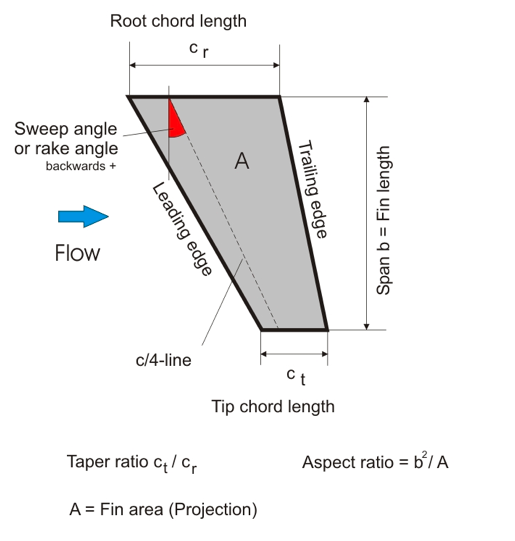

The fin and foil geometries are described as shown below:

These factors have an affect on the fin efficiency: Fin length, taper ratio, aspect ratio, fin area, relative foil thickness, and position of maximum thickness, foil nose radius and foil trailing edge angle.

Lift and Drag

How is the fin side force created?

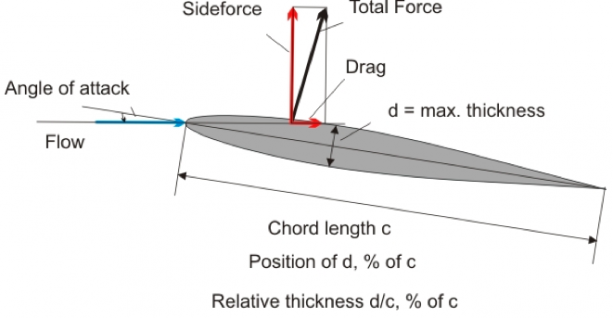

As the fin is nothing but a small wing, we can use the same definitions as in aerodynamics. The forces created are lift and drag, which also define the efficiency of the fin. Since the fin is placed vertically and not horizontally like a wing, the lift becomes a side force. Still, the general physics of produced forces is identical to the lift production of a wing.

The lift of a wing is created by inclining the wing foil against the airflow in a specific angle of attack. The flow around the fin is not symmetric. On the upper part of the foil, the flow must pass a longer way than on the lower part. As a result, the flow has to be quicker on the upper part providing a lower pressure compared to the lower part of the wing. The pressure difference produces the lift force. Lift is always combined with drag, which depends on the foil geometry and friction of the water molecules on the surface of the fin.

More from Dave on page two…